THE SUPPLY CHAIN MANAGERS HANDBOOK

Strong supply chains save lives. Strong supply chains are critical to get health products to clients, wherever and whenever they need them. Supply chain managers have overall responsibility to ensure the continuous supply of health commodities. The Supply Chain Manager’s Handbook is the starting point for anyone interested in learning about and understanding the key principles and concepts of supply chain management for health commodities. The concepts described in this handbook will help supply chain managers that are responsible for improving, revising, designing, operating, and monitoring all or part of a supply chain. The addendum provides an overview of health care supply chain management in the humanitarian response context, to help supply chain managers better prepare and deliver to the people who need relief during a crisis. John Snow, Inc. (JSI) wrote The Supply Chain Manager’s Handbook based on more than 30 years of experience improving public health supply chains in more than 60 countries.

Photo Credit: Audrée Montpetit

Key Concepts

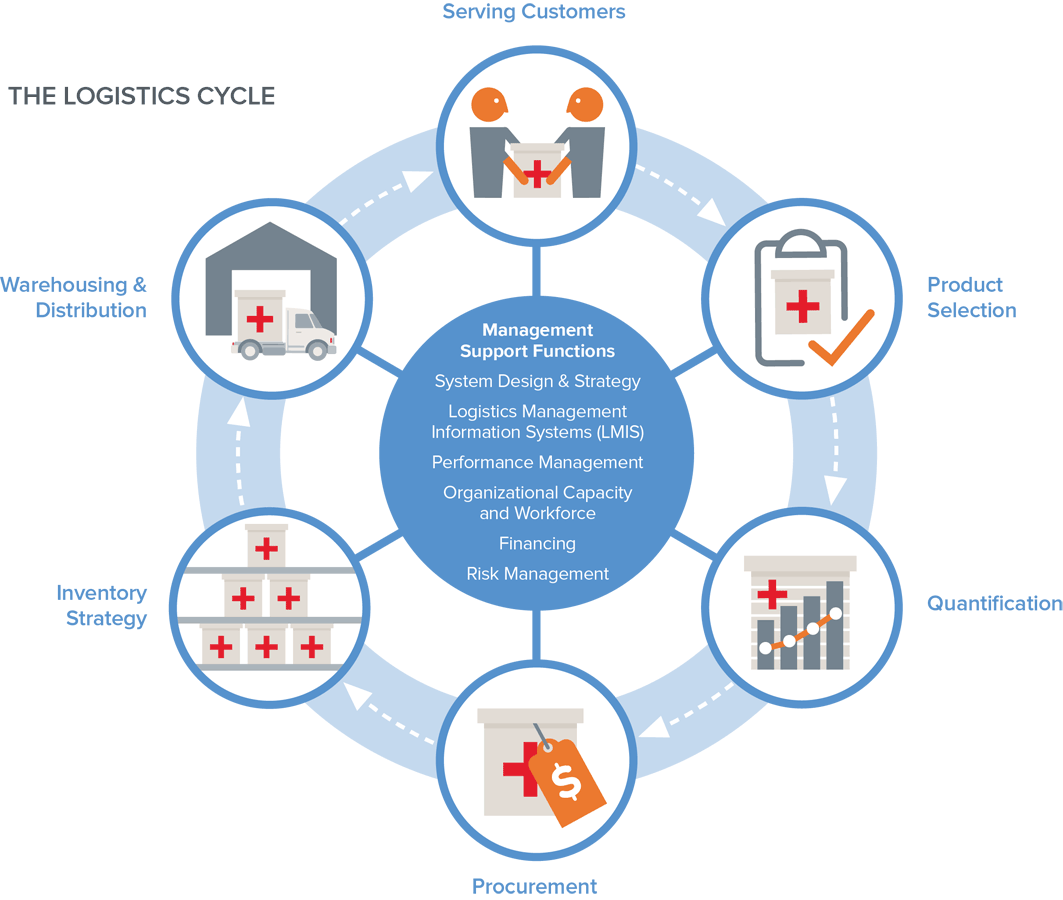

The Logistics Cycle

Supply chain management is a system that integrates activities, people and partners to closer align supply and demand. Logistics activities are the operational component of supply chain management; the logistics cycle is a model to illustrate the activities in a logistics system. The activities in the center of the logistics cycle represent the management support functions that inform and impact the other elements around the logistics cycle. Each activity in the logistics cycle contributes to providing excellent customer service and to ensuring better health outcomes.

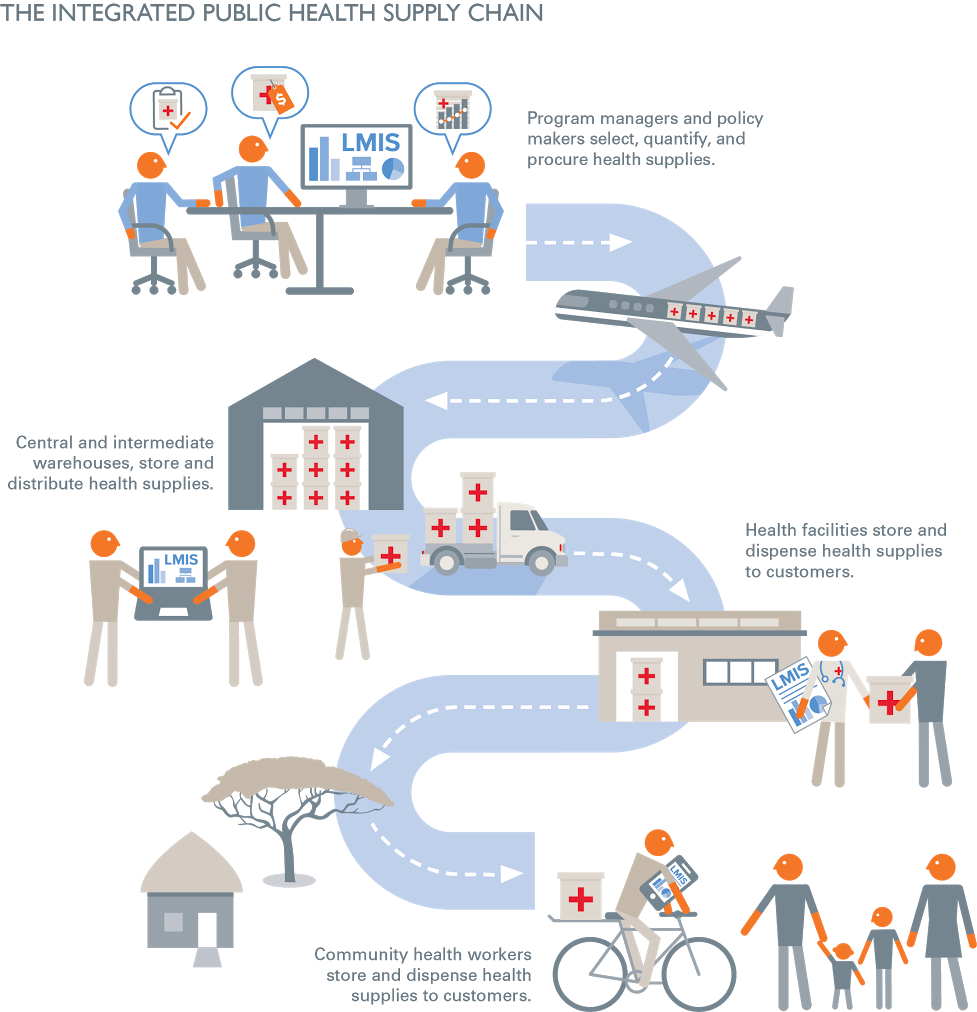

The Integrated Public Health Supply Chain

Integration provides the framework for the activities in the logistics cycle to operate effectively. An integrated supply chain has seamless linkages between the various actors, levels, and functions within a supply chain to maximize customer service, to ensure that clients access quality health care services and supplies wherever and whenever they are needed. Information is visible up and down the chain, there are fewer steps in its processes, and greater coordination and predictability of demand between all of the levels and actors in the system. An integrated supply chain management system has the capacity to learn from errors, self-assess, and adapt through continuous improvement processes.

Chapters

Introduction

A strong health system cannot function without a well-designed, well-operated, and well-maintained supply chain management system—one that can ensure an adequate supply of essential health commodities to the clients who need them.

The supply chain manager needs to know:

- The critically important role played by supply chains in attaining health objectives, and the six rights of supply chain management

- The full range of activities that constitute the supply chain

- The role of the supply chain manager as a steward of the supply chain

- How the concepts of supply chain integration, evolution, and segmentation apply to their own supply chains

Supply chain strategy & design

A supply chain strategy, often referred to as a master plan, is a strategic roadmap aimed at strengthening national supply chain systems to deliver public health commodities. Design can help achieve strategic, tactical, and operational improvements by optimizing the flow of commodities and information, and standardizing the related business processes.

The supply chain manager needs to know:

- The value, components, and approach to developing a supply chain strategy

- Key elements of logistics system design, and the process to system design

- The role of data in supporting design decisions and in meeting the strategic objectives of the supply chain.

- Considerations for logistics system implementation

Logistics management information systems

Effective supply chains depend on end-to-end visibility of the right data of the right quality at the right time, in the hands of the right people in the right place, to make the right decision and take the right action. A hallmark of supply chain maturity is end-to-end visibility of supply and demand data that are used to make decisions and take effective action.

The supply chain manager needs to know:

- The essential data needed to manage a supply chain

- The use of LMIS data

- The tools and processes that enable end-to-end visibility of data

- Considerations for applying technology to improve LMIS

Product selection

In any public health supply chain, health programs must select products. Products selected for use will impact the supply chain; supply chain requirements must be considered during the product selection.

The supply chain manager needs to know:

- The impact of product selection in strengthening procurement, supply chain management, and health service delivery

- The role of national essential medicines lists, standard treatment guidelines, and product registration in product selection

- Particular considerations for standardization of laboratory equipment and supplies for product selection.

Quantification

Quantification is the process of estimating the quantity and cost of the products required for a specific health program (or service), and determining when the products should be procured and delivered to ensure uninterrupted supply of products.

The supply chain manager needs to know:

- The importance of accurately estimating total quantity and cost of products required for health programs and the timing of when they are needed

- The role of quantification in program planning and budgeting, resource mobilization, and procurement

- Key steps in quantification: preparation, forecasting, and supply planning.

Procurement

After a supply plan has been developed as part of the quantification process, products must be procured. Health systems and programs should be strategic about their procurement activities, which should be carefully researched, planned, and monitored, all while abiding by the applicable rules and regulations.

The supply chain manager needs to know:

- The procurement cycle for public health sector systems

- The main steps to conduct a procurement

- Key elements and considerations in crafting the procurement strategy

- The key challenges of procuring health commodities

Inventory strategy

A cohesive inventory strategy will define policies that determine which products to hold in inventory, how much inventory to hold, and where to hold them, and ensures that inventory management decisions are documented and applied consistently across the system.

The supply chain manager needs to know:

- The purpose of holding inventory

- The relationship and trade-offs among inventory policy, the distribution network, service level, and cost

- Range of inventory control systems to select from and their applicability to this particular supply chain situation

- Measures by which to monitor inventory strategy effectiveness and efficiency

Warehousing & distribution

The physical management of products, through various levels of an in-country supply chain,must be carried out in a structured way to ensure that products are protected from harmful environmental conditions or handling, remain accessible, and are maintained in good condition while their management poses no risk of injury to workers.

The supply chain manager needs to know:

- How to carry out the key warehousing activities of receiving, storage and shipping

- How to plan warehouse space requirements and warehouse layout

- Issues to consider in positioning warehouse assets to optimize storage and distribution

- Issues to consider in designing the transportation network and managing the transportation function

Performance management

A well-organized performance management system provides the supply chain manager routine visibility into the functioning of the various components. In the spirit of continuous improvement, performance data can indicate to supply chain managers whether adjustments in policies or procedures are warranted.

The supply chain manager needs to know:

- Status of each component of the cycle for supply chain operations

- Key performance indicators for each functional area of the system

- Available control measures for continuously improving performance

Supply chain workforce

To run effectively, a public health supply chain requires dynamic staff at all levels who are motivated and possess the competencies required to fulfill essential supply chain functions, whose performance is supported and improved through supervision, continuous learning, and opportunities for further development.

The supply chain manager needs to know:

- The staff needed to manage the supply chain

- How to recruit staff

- How to build staff capacity, support them in their work, and monitor their performance

Financing

Health commodities and the supply chains that deliver them need to be adequately resourced. Mobilizing resources and securing a budget line item for health commodities and logistics activities is extremely important to ensure that products are available and that the logistics system operates effectively.

The supply chain manager needs to know:

- Cost of the health care products that are required by the health care system

- Sources of funding for these products and the extent to which commitments are sufficient to meet requirements in the short and long term

- Cost of the supply chain operations to deliver those products to the last mile

- Strategy and plan for efficiently meeting the costs to operate and strengthen the supply chain

Risk management

Risk management is a formal approach to identifying and mitigating sources of disruption and dysfunction within a public health supply chain, helping managers devote planning efforts and management attention where they’re needed most.

The supply chain manager needs to know:

- The basic components of supply chain risk and why it’s important to actively manage

- The benefits of supply chain risk management

- How to identify, evaluate, and prioritize risks to your supply chain performance

- How to identify approaches to manage, monitor, and respond to risk events

- Other strategic applications of risk management

Addendum for Humanitarian Settings

Across the world, the nature of humanitarian crises, natural or man-made, is changing. Strong supply chain management is needed to save lives and deliver crucial health services and life-saving supplies during each phase of an emergency.

The supply chain manager needs to know:

- The basic distinctions between supply chain management in a stable health service context and a humanitarian or emergency response setting

- General practices and considerations for supply chain management of health commodities within each phase of a humanitarian response

- Considerations for transitions between humanitarian response phases

- Where to learn more or access additional resources on the topic

This addendum is made possible by the generous support of the American people through the United States Agency for International Development (USAID). The contents are the responsibility of JSI Research & Training Institute, Inc. (JSI) and do not necessarily reflect the views of USAID/OFDA or the United States government.

This addendum is made possible by the generous support of the American people through the United States Agency for International Development (USAID). The contents are the responsibility of JSI Research & Training Institute, Inc. (JSI) and do not necessarily reflect the views of USAID/OFDA or the United States government.

Logistics Cycle Quick Menu

Click any item to download the chapter as a PDF.